The universally recognised classification used to describe the reaction of plastics to flames is obtained from two tests defined by UL (Underwriters Laboratories, USA). These tests are called: UL-94 HB and UL-94 VB.

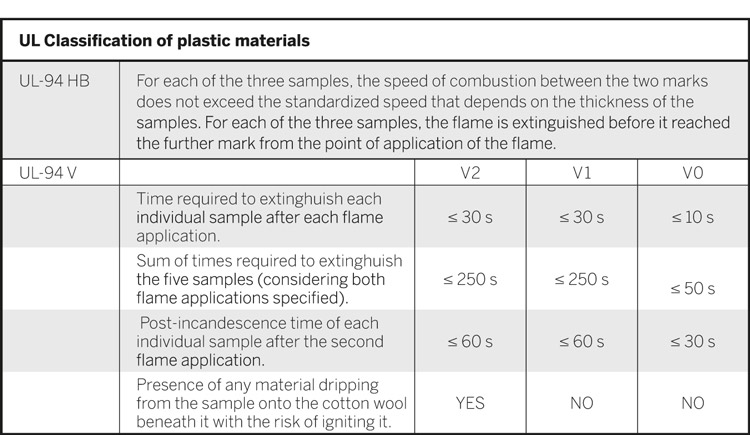

They define four main types of reaction to flames: HB, V2, V1 and V0 with progressively increasing levels of flame resistance.

UL-94 HB (Horizontal Burning)

The test consists of putting a set of three standardized samples of the plastic (in a horizontal position set at an angle of 45° with respect to their own axis) each one in contact for 30 seconds with a flame applied at their bottom free edge. Two marks are present on the samples at standardized distances from the free end.

A material may be classified HB if, for each of the three samples, the following conditions are applicable:

- the speed of burning between the two marks does not exceed a given standardized value that depends on the thickness of the samples being tested;

- the flame is extinguished before the fire reaches the furthest mark from the free edge (that is, from the point of application of the flame).

UL-94 VB (Vertical Burning)

The test entails putting a set of five standardised samples of the plastic (in a vertical position) into contact each one twice for 10 seconds with a flame applied at their bottom free edge. A sheet of cotton wool is placed underneath the samples.

The following parameters are measured:

- the time required to extinguish each individual sample each time the flame is applied;

- the sum of times required to extinguish the five samples (considering both flame applications specified);

- the post-incandescence time of each individual sample after the second flame application;

- whether any material drips from the sample onto the cotton wool set underneath it with a risk of igniting it.

The variables that determine the reaction to the flame include the thickness of the samples and the colouring of the material, in fact, there may be differences between materials with their natural colour and those with an artificial colour and differences depending on the variation in thickness of the sample with the same colour.

Yellow Card:this is a document issued by the Underwriters Laboratories that certifies the reaction of a plastic to flames, following laboratory testing. This constitutes an official recognition of the product's flame resistance.

The 'Yellow Card' indicates the trade name of the product, the manufacturer and related ID number, known as a UL File Number. The flame resistance is certified for specific material thickness and colour. Some material manufacturers carry out flame resistance tests in independent laboratories, using the same test methods as the Underwriters Laboratories. In such cases, a declaration of conformity but no 'Yellow Card' is issued by the manufacturer.

Most of the other ELESA+GANTER products for which no specific indication is given in this regard belong to the UL94-HB category.

There are groups of ELESA+GANTER Standards with UL-94 V0 classification, identified as AE-V0 by the symbol shown in the title.

ELESA products identified as AE-V0 are made of environment-friendly plastics and are free of PBB (Polybromine Biphenyl), PBDE (Polybrominediphenyl Ether) and in particular of Penta-BDE (Pentabromodiphenyl Ether) and of Octa-BDE (Octabromodiphenyl Ether).